Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

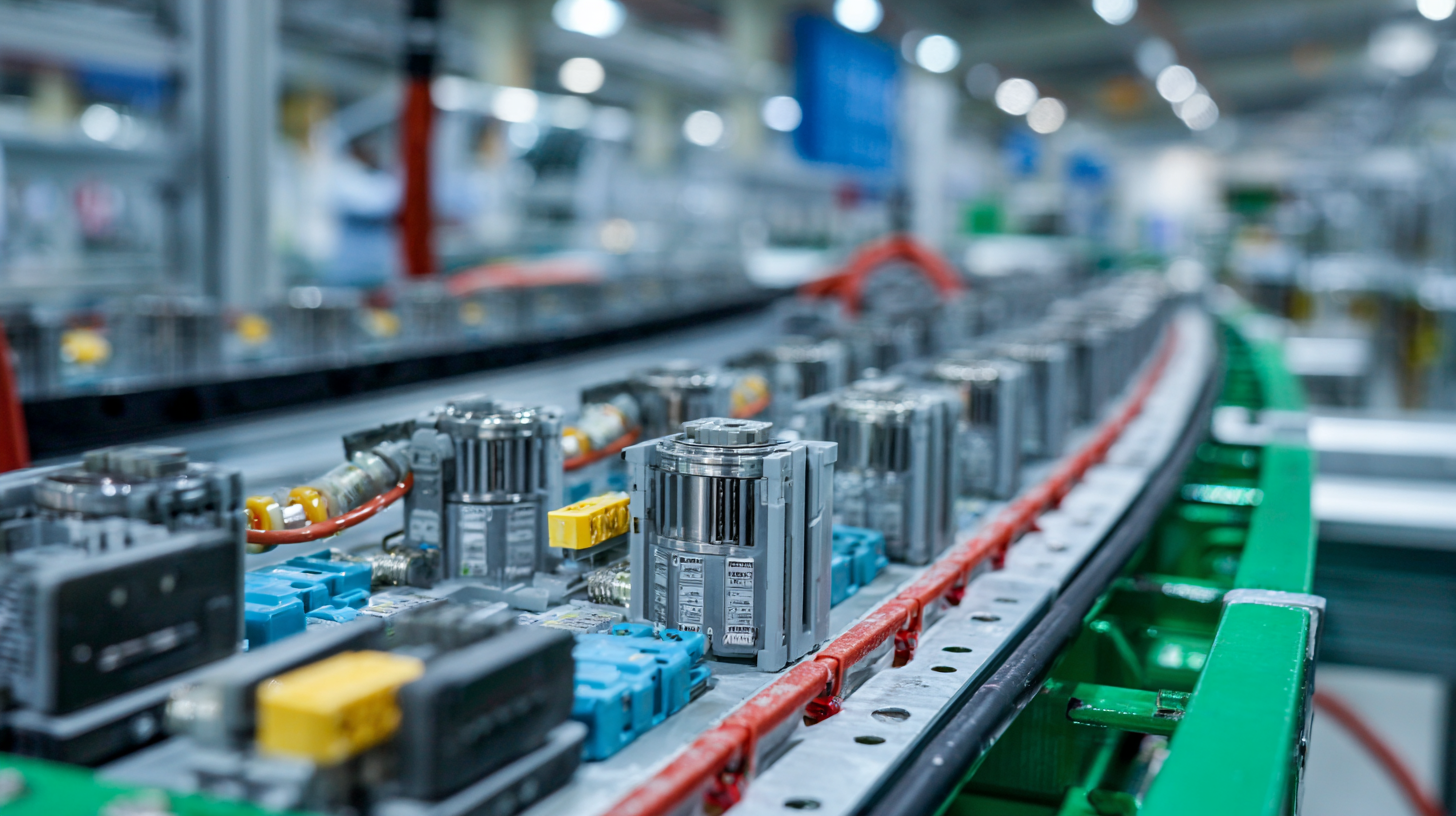

In today's rapidly evolving manufacturing landscape, China stands at the forefront, leveraging innovation and advanced technologies to solidify its global dominance. Among the critical components driving this success are Flexible Busbars, essential in enhancing the efficiency and reliability of electrical systems. As industries worldwide seek solutions that offer adaptability, enhanced performance, and cost-effectiveness, China's top-tier factories are rising to the challenge, producing high-quality Flexible Busbars that meet international standards. This blog delves into the significance of these components, exploring how they embody the strength and ingenuity of Chinese manufacturing, earning global trust and recognition. Join us as we unravel the transformative power of Flexible Busbars and their pivotal role in shaping the future of electrical connectivity across various sectors worldwide.

Flexible busbars have emerged as a key innovation in modern manufacturing, playing a crucial role in enhancing efficiency and performance across various industries. According to a report by Market Research Future, the global busbar market is expected to reach USD 16.4 billion by 2025, driven primarily by the increasing demand for energy-efficient solutions. Flexible busbars, in particular, offer significant advantages, such as reduced weight and improved design flexibility, making them ideal for applications in complex and high-density environments.

One notable benefit of flexible busbars is their ability to minimize electrical resistance, which in turn reduces energy losses. A study published by the International Electrotechnical Commission highlights that the implementation of flexible busbars can lead to energy savings of up to 10% in electrical distribution systems. Additionally, their ease of installation and adaptability allows manufacturers to achieve quicker turnaround times, catering to the fast-paced demands of today's global market. As China continues to solidify its position as a leader in global manufacturing, the adoption of flexible busbars will likely be pivotal in driving innovation and efficiency in various sectors.

The rapid advancement of global manufacturing in China has been accompanied by a growing emphasis on enhancing electrical efficiency. At the heart of this progress lies the flexible busbar, an innovative solution that optimizes power distribution in various applications. Unlike traditional wiring systems, flexible busbars are designed to offer improved conductivity and reduced energy loss, enabling manufacturers to streamline their operations while lowering costs.

Flexible busbars not only provide electrical efficiency but also versatility in design and installation. Their adaptability allows for easy routing in complex layouts, making them ideal for use in manufacturing plants and large-scale industrial settings. As companies continually strive to adopt greener technologies and improve their sustainability metrics, the integration of flexible busbars signifies a step toward efficient energy management and reduced carbon footprints. This transformative approach helps manufacturers maintain their competitive edge while supporting China's vision of becoming a leader in global manufacturing excellence.

| Busbar Type | Material | Cross-Section Area (mm²) | Current Rating (A) | Efficiency (%) | Application |

|---|---|---|---|---|---|

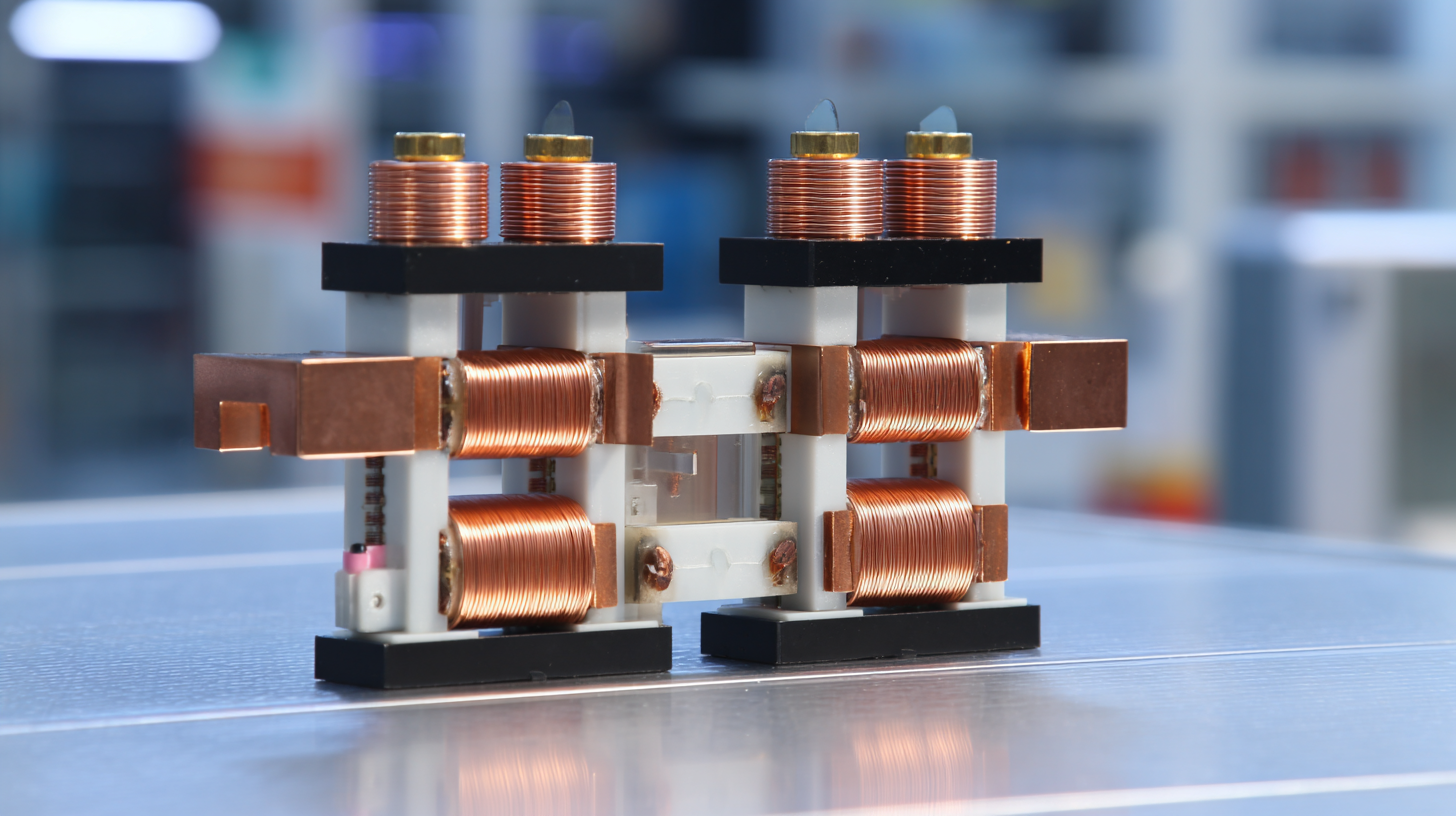

| Flexible Copper Busbar | Copper | 10 | 150 | 98.5 | Power Distribution |

| Flexible Aluminum Busbar | Aluminum | 10 | 120 | 97.0 | Renewable Energy |

| Flexible Bimetallic Busbar | Copper/Aluminum | 15 | 200 | 99.0 | Industrial Automation |

| Flexible Fire-Resistant Busbar | Copper | 12 | 180 | 97.5 | Data Centers |

The integration of flexible busbars in sustainable manufacturing practices is becoming increasingly vital as the global push for efficiency and green technologies intensifies. As reported in recent market analyses, the busbar trunking system market is projected to grow significantly from 2025 to 2034, driven by the rising demand for efficient power distribution solutions. This integration not only supports modern infrastructures but is essential for optimizing energy management in increasingly complex systems, such as smart buildings.

The transition towards electric vehicles is another key area where flexible busbars play a crucial role. Manufacturers are focusing on better interconnect components that enhance power efficiency, enabling longer ranges and shorter recharging times. Innovations in construction and design of busbars are supporting the electric vehicle battery industry, which is adapting to localization initiatives in manufacturing processes. This ensures that production meets the rising demand for effective power management solutions while aligning with sustainable practices. As the market evolves, flexible busbars are set to become indispensable in achieving sustainable manufacturing and powering the next generation of technology.

The transition towards electric vehicles is another key area where flexible busbars play a crucial role. Manufacturers are focusing on better interconnect components that enhance power efficiency, enabling longer ranges and shorter recharging times. Innovations in construction and design of busbars are supporting the electric vehicle battery industry, which is adapting to localization initiatives in manufacturing processes. This ensures that production meets the rising demand for effective power management solutions while aligning with sustainable practices. As the market evolves, flexible busbars are set to become indispensable in achieving sustainable manufacturing and powering the next generation of technology.

The flexible busbar market is poised for impressive growth, highlighting the increasing cost-effectiveness and versatility of these components in modern manufacturing. As industries seek efficient and reliable electrical distribution solutions, flexible busbars provide a unique advantage. With a forecasted expansion from USD 2.8 billion in 2024 to USD 5.2 billion by 2033, achieving a CAGR of 7.5%, their role is becoming more pivotal in the context of global manufacturing.

Recent advancements, such as innovative electrical distribution solutions tailored for panel builders and contractors, underscore the trend towards more adaptable and economically viable options. Flexible busbars cater to this need, offering streamlined assembly processes and improved efficiency. Their versatility not only aids in optimizing production lines but also supports the transformative shift within the automotive sector, where modernization and rapid scalability are crucial for meeting evolving consumer demands. The increasing interest and investment in photovoltaic technologies further emphasize the significance of flexible busbars, as they align with sustainable practices in energy management.

In recent years, the demand for innovative electrical solutions has surged, particularly in the context of China’s robust manufacturing landscape.

Flexible busbars have emerged as a game-changing technology, providing a lightweight and efficient means of power distribution in various applications.

These advanced busbar systems are revolutionizing industries ranging from renewable energy generation to electric vehicles, highlighting their pivotal role in meeting the pressing need for reliable and efficient power management solutions.

One of the key advantages of flexible busbars is their ability to adapt to complex configurations within tight spaces.

This flexibility allows manufacturers to design products that enhance performance while minimizing the use of materials and overall footprint.

Furthermore, by supporting high current ratings and excellent thermal properties, flexible busbars drive technological advancements that are crucial for the electrification initiatives shaping China’s manufacturing prowess.

As industries continue to innovate, the applications of flexible busbars are expected to expand, paving the way for a smarter and more sustainable future.