Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In today's rapidly evolving energy landscape, optimizing Busbar Systems has become a crucial focus for enhancing overall operational efficiency in electrical distribution. As central components in power systems, busbars play a significant role in managing electrical current distribution while minimizing energy losses. However, many businesses overlook the intricacies involved in optimizing these systems, which can lead to reduced performance and increased operational costs. This blog aims to provide actionable insights and expert strategies on how to fine-tune your Busbar Systems, ensuring they function at peak performance. From material selection and design considerations to regular maintenance and advanced monitoring techniques, we will explore a comprehensive approach to not just optimize efficiency but also contribute to the sustainability of your power infrastructure. Join us as we delve into the essential practices that can transform your busbar management for better reliability and productivity.

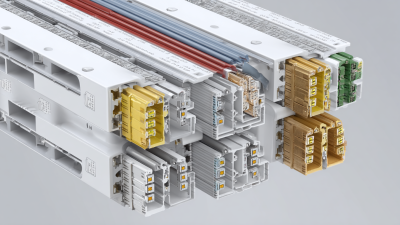

Busbar systems play a crucial role in electrical distribution, acting as a central point for transmitting power between various components. Understanding the fundamentals of busbars is essential, as their design and configuration directly influence the overall efficiency of electrical systems. At the core, a busbar is a conductive material, typically made from copper or aluminum, that efficiently conducts electricity and can be customized to handle specific load requirements. Their placement within facilities can significantly reduce energy losses by minimizing the length of the electrical pathway and optimizing the connection points between power sources and loads.

Efficiency in busbar systems also stems from proper thermal management and load balancing. By ensuring that busbar configurations can handle the heat generated during operation, overheating can be avoided, thus extending the lifespan of the system. Additionally, load balancing is vital; it ensures that the electrical load is evenly distributed across all busbars, preventing potential overloads that could lead to failures or inefficiencies. Emphasizing these fundamentals not only boosts operational reliability but also supports sustainability goals by reducing energy wastage, leading to more efficient electrical systems overall.

| Busbar System Parameter | Description | Efficiency Impact | Recommended Value |

|---|---|---|---|

| Material | Conductive materials used in busbar systems | High-quality materials reduce losses | Copper or Aluminum |

| Cross-sectional Area | Area of the busbar conductor | Larger area reduces resistance | As required by load calculations |

| Length | Distance between connection points | Shorter lengths minimize voltage drop | Minimize as much as feasible |

| Insulation Type | Material used for insulation around busbars | Improper insulation can lead to energy loss | High-quality thermal and electrical insulation |

| Temperature Management | Methods to manage the heat generated | Effective cooling increases lifespan and efficiency | Maintain below manufacturer recommendations |

When optimizing busbar systems, several key factors play a crucial role in determining overall efficiency. One significant factor is the material quality used in busbars. According to a report by the International Copper Association, copper is favored for its exceptional conductivity, which can reach up to 97% while aluminum, albeit lighter and less expensive, has a conductivity of around 61%. Utilizing high-purity materials can significantly reduce energy losses, which are estimated to be as high as 5% in low-quality systems.

Another essential aspect to consider is the design and layout of the busbar system. Properly designed systems can minimize resistance and enhance heat dissipation. A recent study by the Electric Power Research Institute (EPRI) highlighted that busbar arrangements that prioritize minimal lengths and optimized angles can lead to a decrease in thermal and electrical resistance, thus boosting system efficiency by up to 10%. Additionally, regular maintenance and monitoring of connections can help ensure that resistance remains low, further enhancing performance. By focusing on these factors, companies can significantly optimize their busbar systems for improved efficiency.

Innovative materials play a crucial role in enhancing the performance of busbar systems. Traditional copper and aluminum busbars have served well over the years; however, advancements in composite materials and alloys are paving the way for improved efficiency and reduced weight. For instance, the use of high-conductivity copper alloys or even hybrid materials can lead to better thermal management and lower energy losses. These innovative materials not only optimize electrical conductivity but also enhance the durability and longevity of the busbar systems, making them more resistant to environmental factors.

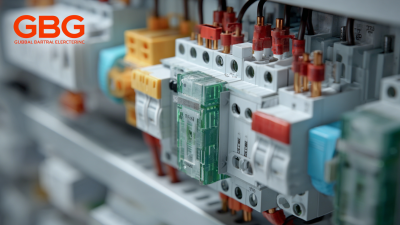

In addition to advanced materials, the adoption of smart technologies is transforming busbar systems. Implementing IoT (Internet of Things) sensors allows for real-time monitoring of temperature and load distribution, enabling proactive maintenance and reducing downtime. Furthermore, the integration of artificial intelligence can help predict performance issues before they arise, allowing for timely interventions. As these technologies continue to evolve, busbar systems can achieve unprecedented levels of efficiency, ensuring they meet the growing demands of modern electrical infrastructure.

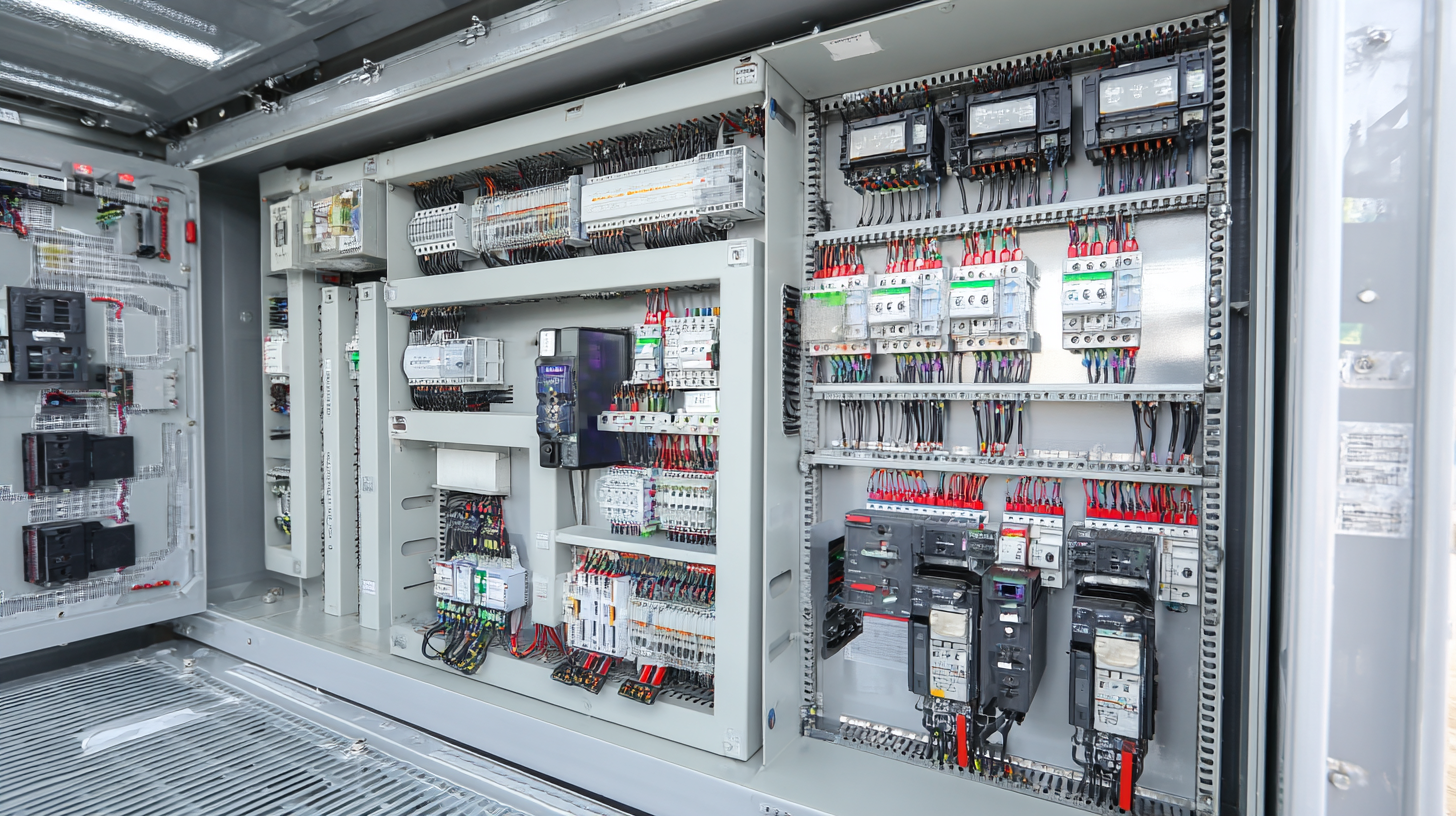

When designing and installing busbar systems, implementing best practices is essential for enhancing efficiency and reliability. According to the International Electrotechnical Commission (IEC), a well-designed busbar system can reduce energy losses by up to 30%, making it a crucial component for businesses looking to optimize performance. Proper material selection, such as high conductivity copper or aluminum, is vital. The choice of materials directly impacts the system's temperature rise and overall longevity, as confirmed by studies from the Institute of Electrical and Electronics Engineers (IEEE).

Tip: Ensure that your busbar system is adequately sized to handle peak loads without overheating. Overloading can lead to severe failures and increased maintenance costs.

Another best practice is to incorporate regular thermal and electrical analysis during the design phase. Using software simulations based on real-world data ensures that the busbar can handle the necessary load and minimizes impedance, which can lead to energy losses. Utilizing advanced monitoring technologies can also provide ongoing insights into the system's performance, allowing for timely interventions and maintenance.

Tip: Regularly schedule preventive maintenance checks to identify wear or weaknesses that could lead to unexpected downtime. Implementing an efficient maintenance protocol can significantly extend the lifespan of your busbar systems.

Regular monitoring and maintenance of busbar systems are crucial for enhancing their efficiency and ensuring reliable power distribution. Temperature gradients within conductors and busbars can lead to inefficiencies and potential failures. By implementing regular inspections, including thermal imaging and current measurement, operators can detect hot spots and imbalances that could negatively impact performance. This proactive approach helps in minimizing the temperature variations, thereby prolonging the life of the busbars and improving overall system reliability.

Recent industry reports project that the global busbar market will grow significantly, from USD 17.2 billion in 2024 to approximately USD 27.0 billion by 2034, reflecting a steady CAGR of 4.6%. This growth is indicative of the increasing adoption of efficient power distribution systems across various sectors. Additionally, the medium power electric vehicle busbar market is expected to see substantial demand, crossing USD 258.3 million by 2024 and continuing to grow at a 20% CAGR from 2025 to 2034. Such statistics emphasize the need for continuous improvement and maintenance strategies in busbar systems to keep pace with industry advancements and rising demand for energy-efficient solutions.