Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the pursuit of enhanced electrical efficiency, optimizing your Busbar End Feed Unit is a critical step that can yield substantial benefits. A well-configured busbar system not only improves power distribution but also minimizes energy losses, leading to lower operational costs and increased lifespan of electrical components. This guide explores essential strategies for maximizing the efficiency of your Busbar End Feed Unit, delving into key design considerations, maintenance practices, and innovative technologies that can significantly boost performance.

By focusing on optimal layout, material selection, and regular inspections, you can ensure that your busbar system operates at its best, delivering reliable and efficient service. Whether you are upgrading existing units or designing new systems, these insights will empower you to make informed decisions that enhance the overall effectiveness of your electrical infrastructure.

Busbar end feed units play a critical role in electrical systems, particularly in ensuring efficient power distribution within various applications. These units are essential for establishing connections between busbar trunking systems and electrical switchgear, allowing seamless power transmission. A well-optimized busbar end feed unit can significantly enhance the overall performance of an electrical installation,

reducing energy losses and increasing reliability.

In high-demand sectors, the latest advancements in busbar systems have shown the capacity to handle substantial current ranges, from low capacities for small consumers to high capacities suitable for multi-storey buildings and industrial applications. For instance, certain busbar systems have been designed to provide efficient power supply options from 40A to as high as 6300A, ensuring that businesses can adapt their power requirements as they grow. Industry reports indicate that optimizing the configurations of these systems can lead to energy savings of up to 20%, demonstrating the pivotal role busbar end feed units play in achieving maximum efficiency in electrical infrastructure.

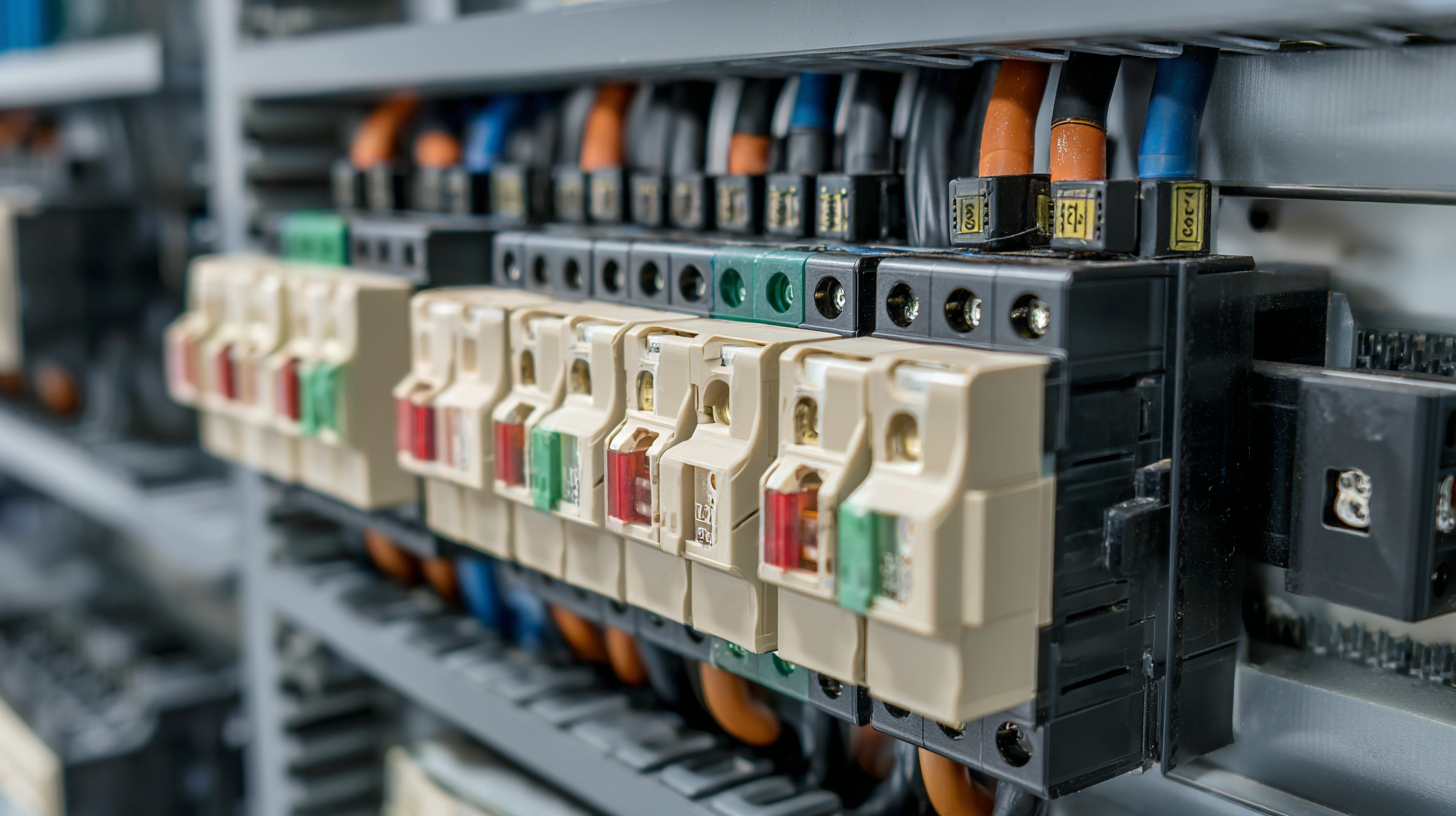

Optimizing a busbar end feed unit is crucial for achieving maximum efficiency in electrical systems. Several key factors significantly influence the performance of these units. First, the design and materials used in the busbar itself play a critical role. High conductivity materials, such as copper or aluminum, minimize resistance and heat losses. Additionally, the configuration of the busbar, including its size and layout, can affect current distribution and overall efficiency.

Another important aspect to consider is the thermal management of the busbar end feed unit. Proper cooling mechanisms are essential to prevent overheating, which can lead to inefficiencies and potential failures. Implementing adequate insulation and ventilation can enhance thermal performance. Furthermore, regular maintenance and monitoring of electrical connections help to identify and rectify issues that may arise over time, ensuring consistent operation at optimal efficiency levels. By focusing on these factors, operators can significantly enhance the functionality and lifespan of busbar end feed units in their systems.

| Parameter | Description | Impact on Efficiency | Recommended Value |

|---|---|---|---|

| Conductor Material | Material used in busbar construction | Higher conductivity materials reduce resistive losses | Copper or Aluminium |

| Cross Sectional Area | Size of the busbar | Larger area reduces current density and heating | Minimum 250 mm² |

| Insulation Type | Type of insulation around busbars | Improves safety and reduces energy loss | Low dielectric loss materials |

| Connection Quality | Integrity of joints and connections | Poor connections increase resistance | Regular inspections and maintenance |

| Ambient Temperature | Operating temperature of the environment | Higher temperatures can reduce efficiency | 20°C to 30°C |

| Load Balance | Distribution of electrical load across phases | Unbalanced loads can cause overheating | Maintain within ± 10% load tolerance |

Innovative technologies are essential for enhancing busbar performance, particularly in the rapidly evolving sectors of electric vehicles (EVs) and renewable energy. Recent advancements in sealing technologies prevent coolant leakage in hybrid and electric drivetrains, significantly improving operational efficiency. As the electric vehicle busbar market is projected to grow at a CAGR of 20.4% from 2025 to 2034, the integration of innovative features will play a pivotal role in meeting future demand and ensuring reliability.

To further optimize busbar end feed units, consider implementing new thermal management techniques. For instance, the adoption of air duct-enhanced designs can improve natural convection heat transfer within the busbar compartments, leading to increased performance and reduced thermal stress. This is critical in maintaining efficiency under varying load conditions, particularly for medium-voltage switchgear systems, where electrical efficiency demands are on the rise.

**Tips:** Ensure regular maintenance checks to identify potential leakage points early. Additionally, investing in training for technical teams on the latest sealing technologies can significantly streamline the optimization process. Lastly, staying updated with industry reports on technological advancements will enable proactive adjustments to your busbar systems for sustained peak performance.

Maintaining and monitoring busbar end feed units are crucial for ensuring their efficiency and longevity. Regular inspections should be conducted to identify any signs of wear or damage. Checking for loose connections and corrosion can prevent potential failures. It's important to establish a maintenance schedule that includes cleaning the busbars and ensuring proper insulation.

Maintaining and monitoring busbar end feed units are crucial for ensuring their efficiency and longevity. Regular inspections should be conducted to identify any signs of wear or damage. Checking for loose connections and corrosion can prevent potential failures. It's important to establish a maintenance schedule that includes cleaning the busbars and ensuring proper insulation.

Tips: Always ensure that the busbar connections are tightly secured, as loose fittings can lead to overheating and reduce overall performance. Additionally, invest in thermal imaging technology to detect hotspots that may indicate trouble before they become serious issues.

Monitoring the operational parameters of your busbar end feed units is equally important. Utilizing real-time monitoring systems can alert operators to irregularities in power flow or temperature spikes, allowing for timely interventions. Keeping track of performance data can also help in forecasting maintenance needs and planning upgrades.

Tips: Set up automated alerts for temperature thresholds to catch potential problems early. Regularly reviewing performance logs can also aid in identifying trends that suggest when components may need replacing.

The optimization of busbar end feed units is crucial for enhancing efficiency in electrical distribution systems. Several case studies illustrate the effectiveness of strategic improvements. For instance, a manufacturing plant implemented a redesign of their busbar end feed unit, incorporating advanced materials to reduce resistive losses. This upgrade led to a significant decrease in energy consumption, as well as an increase in overall system reliability.

Another successful example comes from a commercial building that faced frequent power quality issues. By conducting a thorough analysis of their existing busbar system, they identified key areas for optimization, including the installation of insulated busbars and enhanced cooling mechanisms. These changes resulted in not only improved power flow but also extended the lifespan of their electrical components. The lessons learned from these case studies highlight the importance of regularly assessing busbar end feed units to achieve maximum operational efficiency.