Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

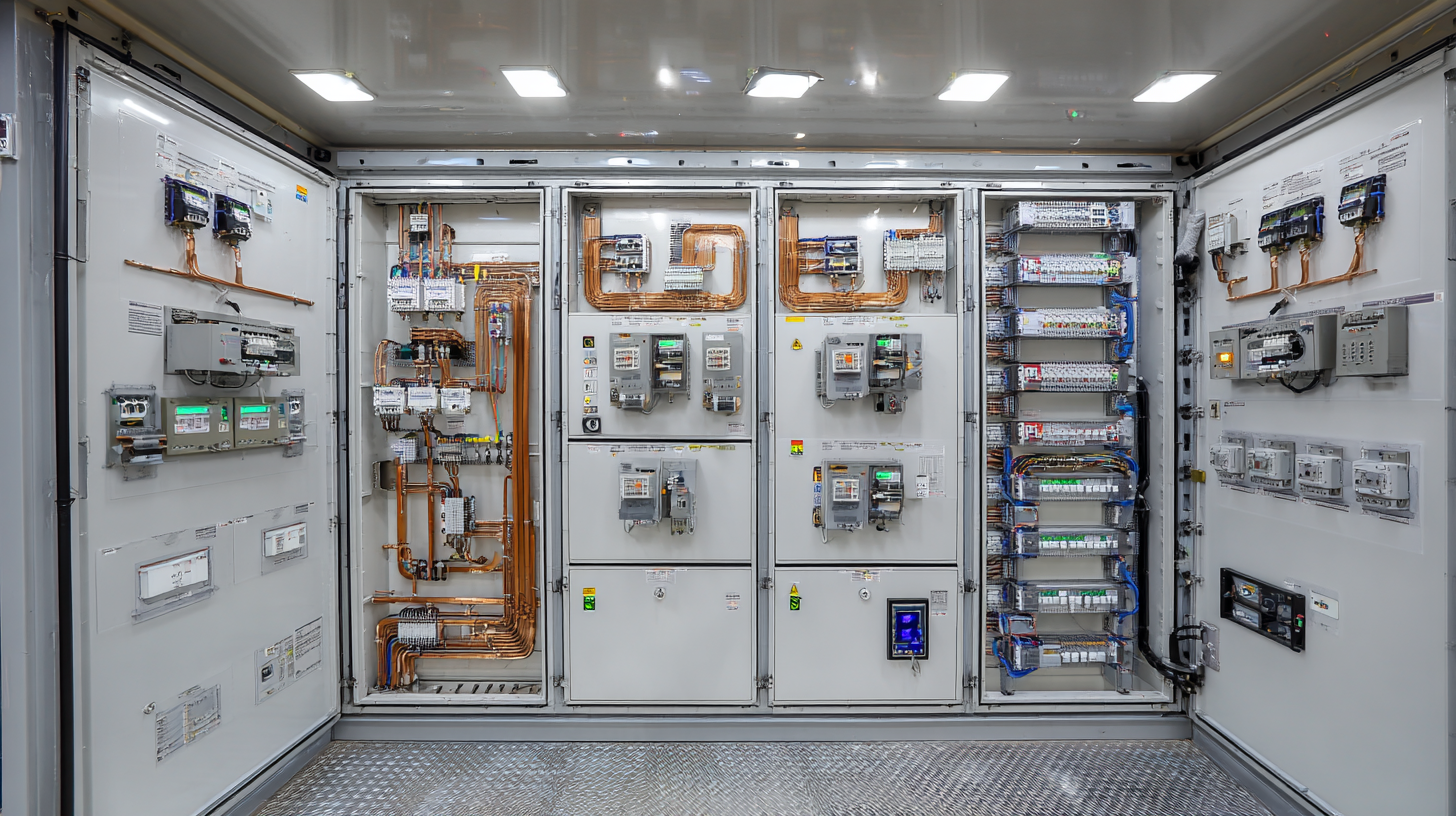

In the rapidly evolving landscape of industrial technology, the importance of optimizing after-sales support and minimizing maintenance costs cannot be overstated, particularly for essential components like the Copper Dense Busway. As industries strive to enhance efficiency and reduce operational expenditures, understanding the intricate relationship between effective support systems and cost management becomes crucial. This blog will explore the latest trends shaping the industry in 2025 and provide an ultimate guide to maximizing the performance and longevity of Copper Dense Busways. By integrating advanced support strategies and proactive maintenance practices, businesses can not only ensure uninterrupted operations but also drive down costs significantly, paving the way for a more sustainable and profitable future. Join us as we delve into actionable insights and best practices that will empower organizations to fully harness the potential of their Copper Dense Busway systems.

Maximizing after-sales support is crucial for the success of busway systems, particularly in enhancing customer satisfaction and minimizing maintenance costs. Key strategies involve establishing strong communication channels between manufacturers and end-users. This ensures that users have easy access to technical support and can obtain timely assistance when facing issues. Implementing a comprehensive training program for customers can also empower them to handle routine maintenance and troubleshooting, leading to fewer service calls and lower costs.

Moreover, investing in localized support teams, like the recent branch establishment in Mexico, can significantly improve response times and service quality. Having dedicated professionals on the ground who understand the specific needs of the regional market enhances the ability to provide effective consulting and immediate after-sales service. By proactively engaging with customers through regular check-ins and feedback sessions, busway system providers can identify potential issues early and adjust their offerings accordingly, fostering a long-lasting relationship and ensuring operational efficiency.

Maintaining the performance of copper dense busways is crucial for ensuring their longevity and operational efficiency. Regular maintenance plays a pivotal role in identifying potential issues before they escalate into costly repairs. By implementing a proactive maintenance strategy, businesses can monitor wear and tear, inspect connections, and ensure optimal performance levels. This preventive approach not only extends the lifespan of the busway but also minimizes downtime, which can significantly impact productivity.

Maintaining the performance of copper dense busways is crucial for ensuring their longevity and operational efficiency. Regular maintenance plays a pivotal role in identifying potential issues before they escalate into costly repairs. By implementing a proactive maintenance strategy, businesses can monitor wear and tear, inspect connections, and ensure optimal performance levels. This preventive approach not only extends the lifespan of the busway but also minimizes downtime, which can significantly impact productivity.

Moreover, understanding the specific maintenance requirements of copper dense busways can lead to substantial cost savings. It’s essential to schedule routine checks and cleanings that cater to the unique characteristics of copper materials. For instance, addressing oxidation and corrosion promptly can prevent performance degradation and reduce the frequency of major maintenance interventions. By investing in training for maintenance staff and utilizing advanced diagnostic tools, operations can further enhance their ability to maintain these systems efficiently, ultimately leading to reduced maintenance costs and improved overall performance.

When it comes to maintaining a best copper dense busway, traditional maintenance practices can often come with high costs and extensive downtime. Therefore, exploring cost-effective alternatives is essential to maximizing after-sales support while minimizing maintenance expenses. One effective strategy is to implement predictive maintenance technologies. These systems use data analytics to forecast potential issues before they escalate, allowing for timely interventions that save both time and money.

Another tip is to invest in training your maintenance team. Well-equipped staff who understand the intricacies of the busway system can significantly reduce errors and the frequency of unplanned repairs. Offering regular workshops and refreshers can empower your team with the latest techniques and best practices, ultimately leading to lower maintenance costs.

Additionally, consider using high-quality materials and components for repairs and upgrades. While the initial investment may be higher, the longevity and reliability of superior materials can drastically reduce the frequency of maintenance required, providing savings in the long run.

Embracing these alternative practices not only enhances the efficiency of your operations but also ensures a robust after-sales service that keeps your busway running smoothly.

As we approach 2025, the landscape of after sales support in the copper dense busway market is poised for significant transformation, driven by emerging technologies. According to a recent report by MarketsandMarkets, the global market for after sales services is projected to reach USD 1.7 trillion by 2025, reflecting an annual growth rate of over 10%. This growth is fueled by advancements in artificial intelligence (AI) and the Internet of Things (IoT), which are redefining how manufacturers interact with customers post-purchase. Companies are increasingly leveraging predictive maintenance tools powered by AI to anticipate equipment failures before they occur, minimizing downtime and enhancing customer satisfaction.

Furthermore, the integration of augmented reality (AR) into after sales support provides operators with real-time assistance for troubleshooting and maintenance tasks. A study by Gartner predicts that by 2025, 75% of service organizations will use AR and virtual reality (VR) to enhance the customer experience. This technology enables technicians to visualize complex systems, thereby reducing the time and costs associated with maintenance. Additionally, cloud-based platforms are facilitating seamless communication and data sharing between manufacturers and clients, allowing for more proactive after sales support. By embracing these emerging technologies, companies can significantly improve their after sales service efficiencies while simultaneously lowering maintenance costs, ensuring a competitive edge in the evolving market.

After sales support plays a crucial role in managing the lifecycle costs of busways, particularly those made from copper due to their high conductivity and efficiency. Effective after sales services can significantly enhance the longevity and performance of these systems. By ensuring timely maintenance and addressing potential issues promptly, companies can greatly reduce unexpected failures and associated repair costs. Implementing a robust customer support system not only helps in diagnosing problems but also in providing valuable insights into the proper handling and operation of copper dense busways.

Moreover, the impact of after sales support extends beyond immediate cost savings. Strong support structures can lead to improved customer satisfaction, fostering long-term relationships and brand loyalty. Customers who feel confident in their after sales services are likely to choose the same provider for future projects, creating a steady stream of revenue. Additionally, comprehensive training for maintenance staff as part of the after sales strategy can prevent misuse and optimize the operational efficiency of busways, further minimizing maintenance costs over the product's lifecycle. This alignment of after sales efforts with lifecycle management ultimately positions companies for sustainable success in the competitive busway market.