Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

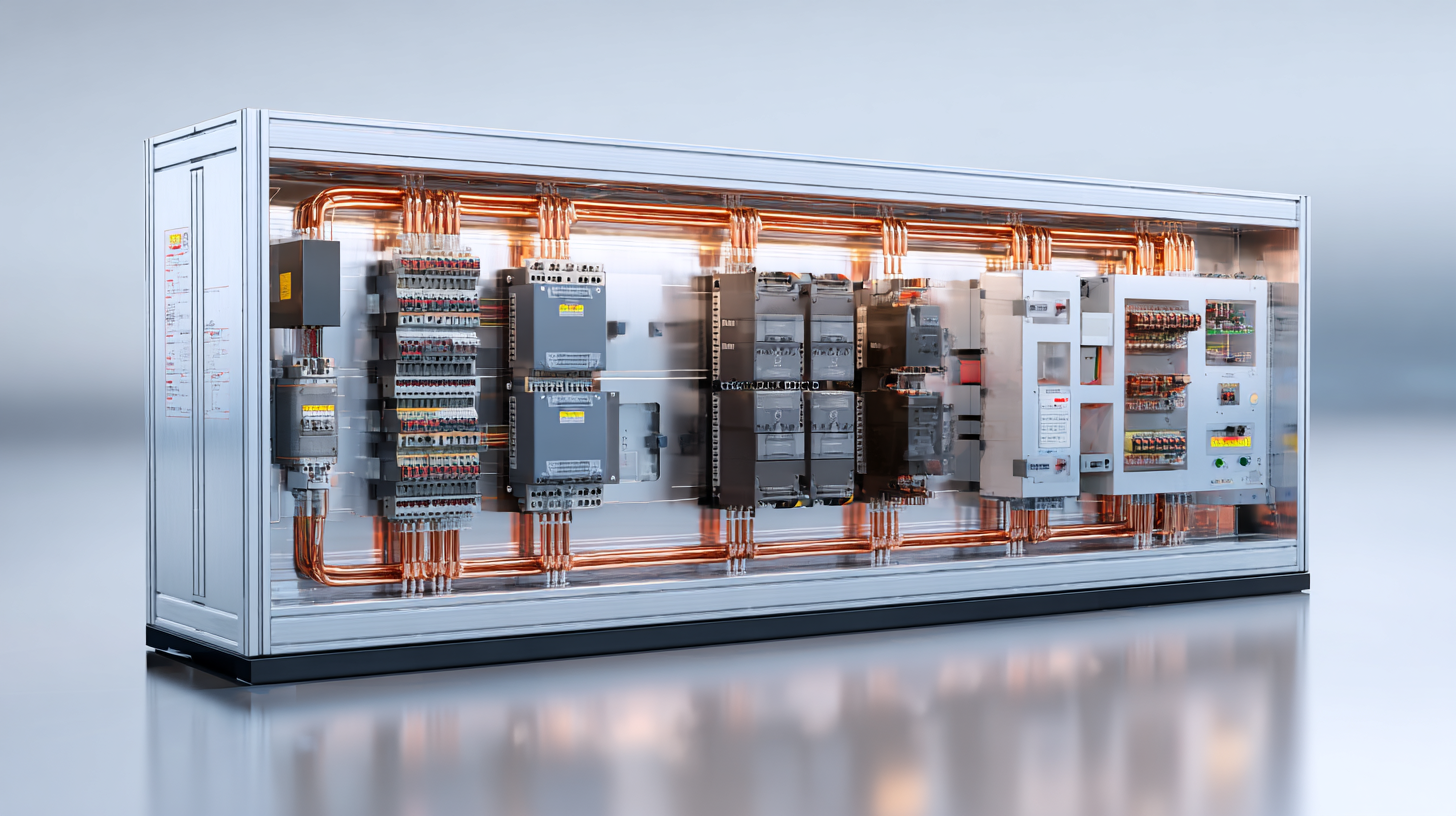

In an era where efficiency and reliability are paramount in electrical distribution systems, the significance of high-quality Busbar Busduct manufacturing cannot be overstated. As the global demand for energy distribution solutions steadily rises, China has emerged as a key player in producing cutting-edge Busbar Busduct systems that meet international standards. This blog aims to guide readers through the intricate world of Busbar Busduct manufacturing, highlighting the innovative technologies and practices that Chinese manufacturers employ to excel in this field. From the selection of premium materials to the implementation of rigorous testing protocols, we will explore how these factors contribute to the development of superior Busbar Busducts that cater to various industrial needs. Join us as we delve into the remarkable journey of China’s manufacturing prowess in Busbar Busducts, setting a benchmark for global excellence.

In an era where efficiency and reliability are paramount in electrical distribution systems, the significance of high-quality Busbar Busduct manufacturing cannot be overstated. As the global demand for energy distribution solutions steadily rises, China has emerged as a key player in producing cutting-edge Busbar Busduct systems that meet international standards. This blog aims to guide readers through the intricate world of Busbar Busduct manufacturing, highlighting the innovative technologies and practices that Chinese manufacturers employ to excel in this field. From the selection of premium materials to the implementation of rigorous testing protocols, we will explore how these factors contribute to the development of superior Busbar Busducts that cater to various industrial needs. Join us as we delve into the remarkable journey of China’s manufacturing prowess in Busbar Busducts, setting a benchmark for global excellence.

The rapidly growing busbar busduct manufacturing industry in China has established a significant global footprint. However, one of the primary challenges faced by manufacturers is maintaining stringent quality control standards. According to a report by Research and Markets, the global busbar market is expected to reach $25 billion by 2025, with a notable requirement for precision in production to meet diverse application needs. This burgeoning demand implies heightened scrutiny of quality assurance processes.

Manufacturers often encounter obstacles related to material consistency, production techniques, and adherence to international standards. For instance, the International Electrotechnical Commission (IEC) standardizes many aspects of busbar busduct manufacturing, yet deviations are frequently observed in the application of these standards across different factories. A study from the International Journal of Electrical Engineering & Technology highlights that up to 30% of busbar systems fail to meet certified criteria, leading to performance inefficiencies and increased risk of electrical failures. Thus, it's crucial for manufacturers to implement robust quality management systems to mitigate these issues and enhance their competitive edge in the global market.

The performance of busbar busducts is significantly influenced by material selection, which plays a critical role in ensuring efficiency and longevity. In the manufacturing of these electrical systems, the choice of conductive materials directly affects the electrical resistance and thermal performance. For instance, copper and aluminum are the two most commonly used materials due to their excellent conductivity. However, the specific application requirements may dictate which material is more suitable, considering factors such as weight, cost, and corrosion resistance.

Moreover, the insulation materials used in busbar busducts also contribute to their overall performance. High-quality insulation is essential to prevent energy losses and ensure safety in high-voltage applications. Materials like PVC, silicone, and epoxy resin are often utilized for their durability and resistance to environmental factors. Selecting the right combination of conductive and insulating materials not only enhances the efficiency of busbar systems but also extends their service life, which is vital in meeting the growing energy demands globally.

The busbar busduct systems have long been recognized for their reliability and efficiency in power transmission. However, design flaws and performance issues have prompted innovations to enhance their efficacy. Recent developments have introduced a three-dimensional eddy-current field model specifically designed to calculate eddy-current losses within compact bus duct systems. This innovative approach aims to address inefficiencies and improve overall system performance, which is critical in industries that demand high power levels.

The busbar busduct systems have long been recognized for their reliability and efficiency in power transmission. However, design flaws and performance issues have prompted innovations to enhance their efficacy. Recent developments have introduced a three-dimensional eddy-current field model specifically designed to calculate eddy-current losses within compact bus duct systems. This innovative approach aims to address inefficiencies and improve overall system performance, which is critical in industries that demand high power levels.

Furthermore, advancements in numerical methods for calculating the impedance of rectangular bus ducts are paving the way for more precise and efficient designs. By utilizing integral equation methods alongside partial inductance theory, engineers can better predict the electrical behavior of busbar systems under various operational conditions. Additionally, modern solutions incorporate thermal analysis to prevent overheating risks by employing gas sensing technologies, which detect volatile gases generated from insulation degradation. Such proactive measures are essential in ensuring the longevity and safety of high-current power supply systems, particularly in complex infrastructures.

Manufacturing busbar busducts in China has gained global recognition, not only for efficiency but also for stringent regulatory compliance. The growing demand for energy-efficient systems has prompted Chinese manufacturers to adapt to international standards. According to a report by Research and Markets, the global busbar systems market is expected to reach USD 18 billion by 2025, with a significant contribution from China, which has become a hub for high-quality manufacturing practices.

Navigating regulatory compliance in busbar busduct production is critical for manufacturers aiming to compete in the global arena. Recent evaluations show that nearly 70% of companies face challenges in adhering to the diverse standards set by countries worldwide. For instance, the International Electrotechnical Commission (IEC) standards are essential for ensuring safety and performance. Manufacturers in China are increasingly investing in compliance training and certification processes to meet these international benchmarks, thus ensuring that their products not only meet but exceed market expectations. As a result, Chinese busbar busduct manufacturers are well-positioned to lead in innovation and quality, effectively addressing both domestic and international regulatory landscapes.

This chart illustrates the production compliance rates of busbar busduct manufacturers across various regions, highlighting their adherence to international regulations.

The global bus duct market is on a trajectory of significant growth, projected to expand from approximately USD 12.91 billion in 2024 to USD 16.60 billion by 2029, reflecting a robust CAGR of 5.2%. This growth is driven by the increasing demand for efficient power distribution systems across various sectors, including commercial, industrial, and infrastructure development. With technological advancements and rising urbanization, manufacturers are urged to innovate and refine their strategies to capture more market share.

As the market evolves, several trends are shaping manufacturing strategies in the busbar busduct sector. The emphasis on energy efficiency and sustainability is leading companies to adopt eco-friendly materials and production processes. Furthermore, the growing adoption of smart grid technology is compelling manufacturers to integrate advanced monitoring and control systems within their bus duct solutions.

**Tip:** Companies looking to enter the bus duct market should consider investing in research and development to stay ahead of emerging trends. They should also focus on building strategic partnerships that can enhance their product offerings and market reach. Establishing a strong online presence can also prove beneficial in attracting potential customers in an increasingly digital world.