Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

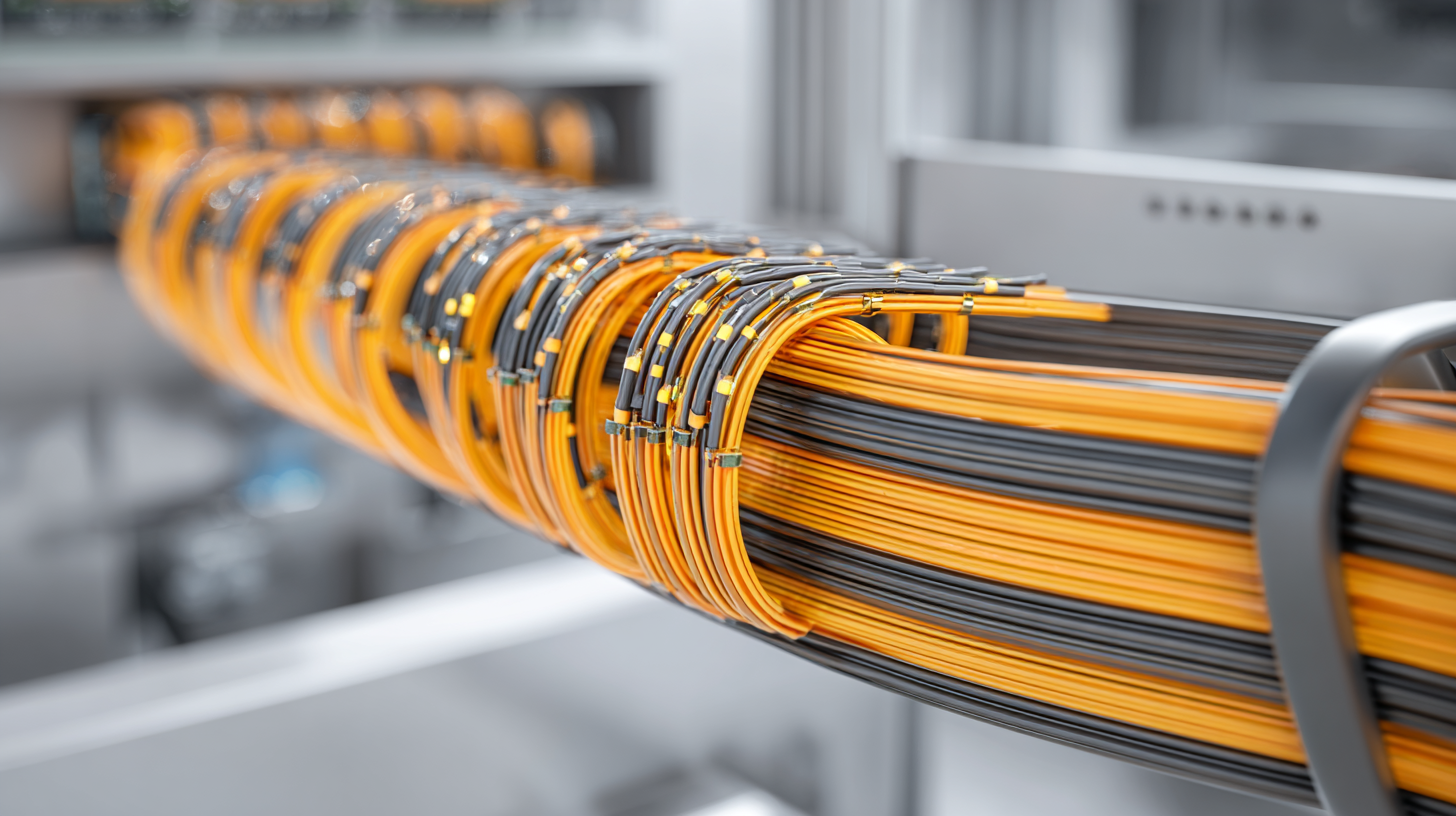

In the ever-evolving landscape of electrical engineering, the choice of components plays a crucial role in the efficiency and functionality of electrical systems. Among these components, the Flexible Busbar stands out as a vital element, offering versatile solutions for various electrical applications. With advancements in technology and the increasing demand for adaptable electrical systems, understanding the different types of Flexible Busbars available is essential for engineers and project managers alike.

As we approach 2025, the need for more efficient, compact, and lightweight electrical solutions has prompted innovations in the design and materials used for Flexible Busbars. This guide aims to provide a comprehensive overview of the types of Flexible Busbars, their applications, and key considerations for selecting the ideal option for your upcoming projects. By delving into the characteristics and benefits of various Flexible Busbar types, you will be better equipped to make informed decisions that align with your project's requirements and objectives.

When selecting a flexible busbar for your electrical projects in 2025, several key factors should be at the forefront of your decision-making process. First and foremost, consider the electrical specifications required for your application, including current ratings, voltage levels, and the overall power demand. Understanding these requirements will help you choose a busbar that can handle the necessary load without compromising performance or safety.

**Tips:** Always verify the material composition of the busbar, as this impacts both conductivity and durability. Copper and aluminum are common choices, with copper offering superior conductivity but at a higher cost. Additionally, explore the environmental considerations, such as temperature variations and humidity levels, since these factors can significantly influence the busbar’s long-term reliability.

Another critical aspect to evaluate is the design flexibility and ease of installation. A flexible busbar should be adaptable to various layouts and configurations while ensuring secure connections. Review the installation guides and, if possible, seek user experiences to gauge how efficiently the busbar performs in real-world scenarios. This insight will not only help in making an informed choice but also in optimizing the overall effectiveness of your electrical system.

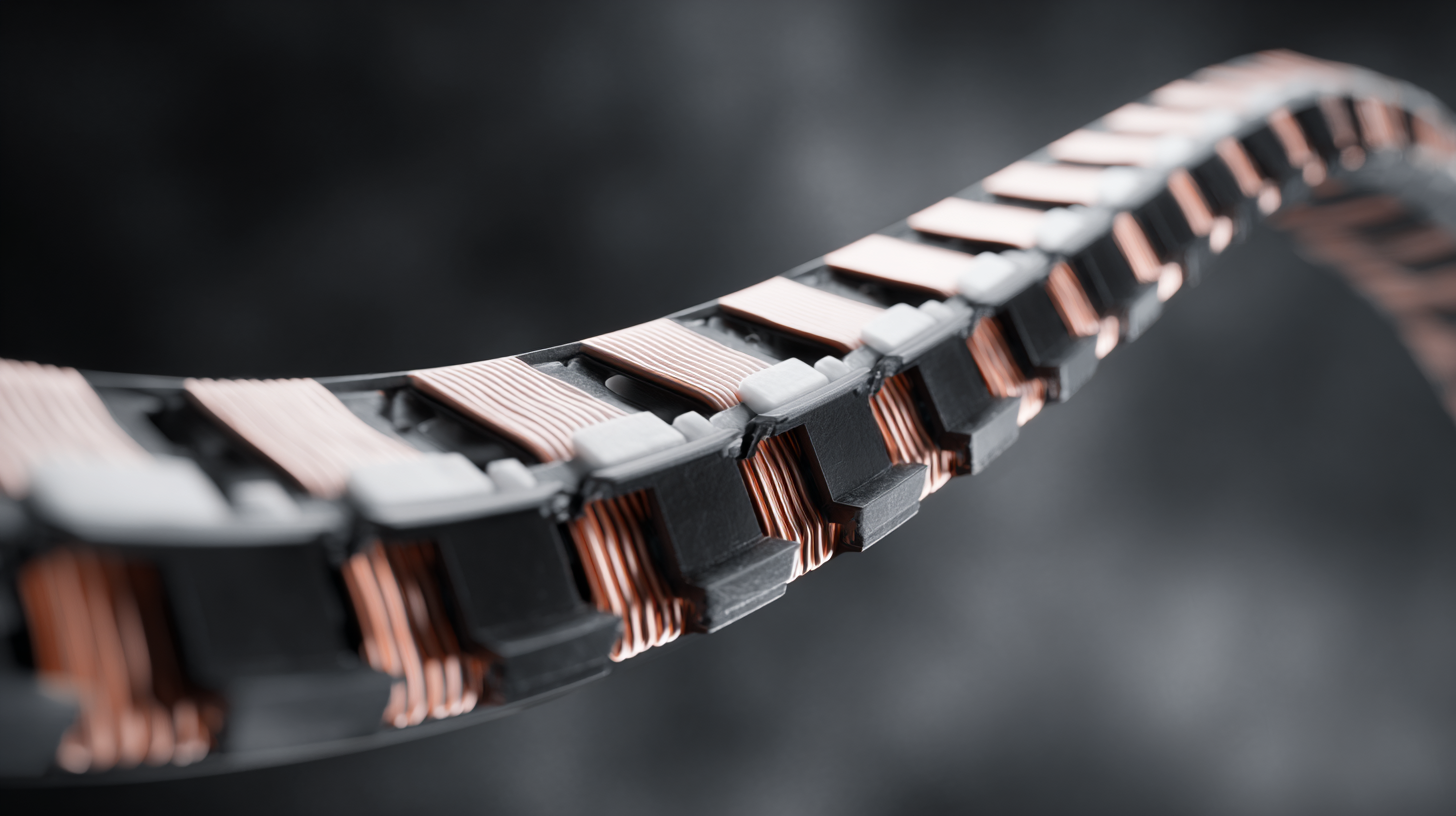

When selecting the right flexible busbar for your electrical projects in 2025, understanding the different types available on the market is crucial. Flexible busbars can typically be categorized into several main types: flat, segmented, and tubular designs. According to a recent industry report by Grand View Research, the global flexible busbar market is projected to reach USD 1.5 billion by 2025, driven by increasing demand in renewable energy applications and electric vehicle charging infrastructure. Each type offers distinct advantages, such as improved space efficiency with flat designs or enhanced current distribution with segmented configurations.

Flat flexible busbars are particularly favored for their ease of installation and versatility in compact spaces. They provide efficient thermal management and are often employed in data centers and industrial applications where reliability is paramount. On the other hand, tubular busbars tend to cater to higher current requirements and are commonly utilized in large-scale power distribution. A report by Market Research Future estimates that the demand for flexible busbars will grow at a CAGR of 6.2% from 2020 to 2025, indicating a robust trend towards advanced connectivity solutions in electrical systems. This growth is largely attributed to innovations in materials and design, enhancing performance while ensuring compliance with evolving safety standards.

When selecting the best flexible busbar for electrical projects in 2025, evaluating material options is crucial for achieving enhanced conductivity and durability. Materials like copper and aluminum are popular choices due to their excellent electrical conductivity. Copper, with its superior conductivity, offers low resistive losses, making it ideal for high-performance applications. However, its higher cost can be a drawback for projects with budget constraints. In contrast, aluminum is lighter and more affordable, but it may require larger cross-sectional areas to match copper’s conductivity.

In addition to base materials, coatings and treatments can significantly affect the performance of flexible busbars. Tin or silver plating can enhance conductivity while providing protection against corrosion. The selection of insulation materials is also vital, as high-temperature resistant options can improve durability and extend the lifespan of the busbar in demanding environments. Therefore, a thorough assessment of both base and additional materials ensures that you choose a flexible busbar that meets the specific requirements of your electrical projects, striking a balance between performance and cost-effectiveness.

When designing a flexible busbar for your electrical projects, it's crucial to size it correctly for the specific electrical loads it will serve. The improper sizing of a busbar can lead to overheating, inefficiency, or even system failure. Therefore, understanding the current requirements and load conditions is essential for optimal performance.

**Tips:** Assess both the maximum and continuous current requirements of your electrical system. It's important to factor in any potential surges or peaks in load that could affect the busbar's performance. Additionally, consider the environmental conditions, such as temperature and humidity, which can influence the materials and design choices of your busbar.

When tailoring your design, also think about the future scalability of your system. A flexible busbar should ideally accommodate changes in load demands without needing significant redesigns. This adaptability is key in modern engineering projects, especially in sectors like defense and aerospace, where operational flexibility is paramount. Evaluating the system's layout and potential upgrades will allow you to create a more resilient and effective electrical infrastructure.

| Busbar Type | Material | Current Rating (A) | Application | Temperature Rating (°C) |

|---|---|---|---|---|

| Flexible Copper Busbar | Copper | 600 | Power Distribution | -40 to 90 |

| Flexible Aluminum Busbar | Aluminum | 500 | Renewable Energy | -40 to 80 |

| Tin Plated Copper Busbar | Copper with Tin Coating | 400 | Commercial Power Systems | -40 to 100 |

| Flexible Copper Nickel Busbar | Copper-Nickel Alloy | 300 | Marine Applications | -40 to 85 |

| High-Temperature Flexible Busbar | Copper | 800 | Industrial Motors | -40 to 120 |

When it comes to the installation and maintenance of flexible busbars in modern electrical projects, adhering to best practices is crucial for ensuring efficiency and longevity. According to a report by the Electrical Safety Foundation International (ESFI), improper installation can lead to up to 30% of electrical failures in commercial applications. To mitigate these risks, it is essential to follow the manufacturer's guidelines meticulously during installation, which typically includes ensuring that busbars are securely mounted to prevent movement and thermal expansion issues. Furthermore, maintaining adequate airflow around the busbars can significantly reduce overheating, which is one of the leading causes of electrical equipment failure.

Regular inspections are also vital for the upkeep of flexible busbars. The Institute of Electrical and Electronics Engineers (IEEE) recommends performing thermal imaging scans at least once a year to detect hotspots that can indicate potential failure points. Additionally, routine cleaning and tightening of connections can prevent oxidation and increased resistance, which are detrimental to system performance. By implementing these best practices, electrical engineers can enhance the reliability and efficiency of their projects while extending the lifespan of their flexible busbar systems.