Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the realm of electrical systems, Bus Duct Electrical systems stand out as a crucial component for modern industrial and commercial applications. According to a report by the U.S. Department of Energy, businesses can enhance their energy efficiency by up to 10% by optimizing power distribution systems like bus ducts. These systems not only facilitate the safe and efficient distribution of electrical power but also reduce energy loss and lower operational costs.

As the demand for sustainable and energy-efficient solutions grows, understanding the intricacies of Bus Duct Electrical systems becomes essential for facility managers and engineers alike. This blog aims to delve into what bus duct electrical systems are, their operational principles, and their significant impact on overall energy efficiency.

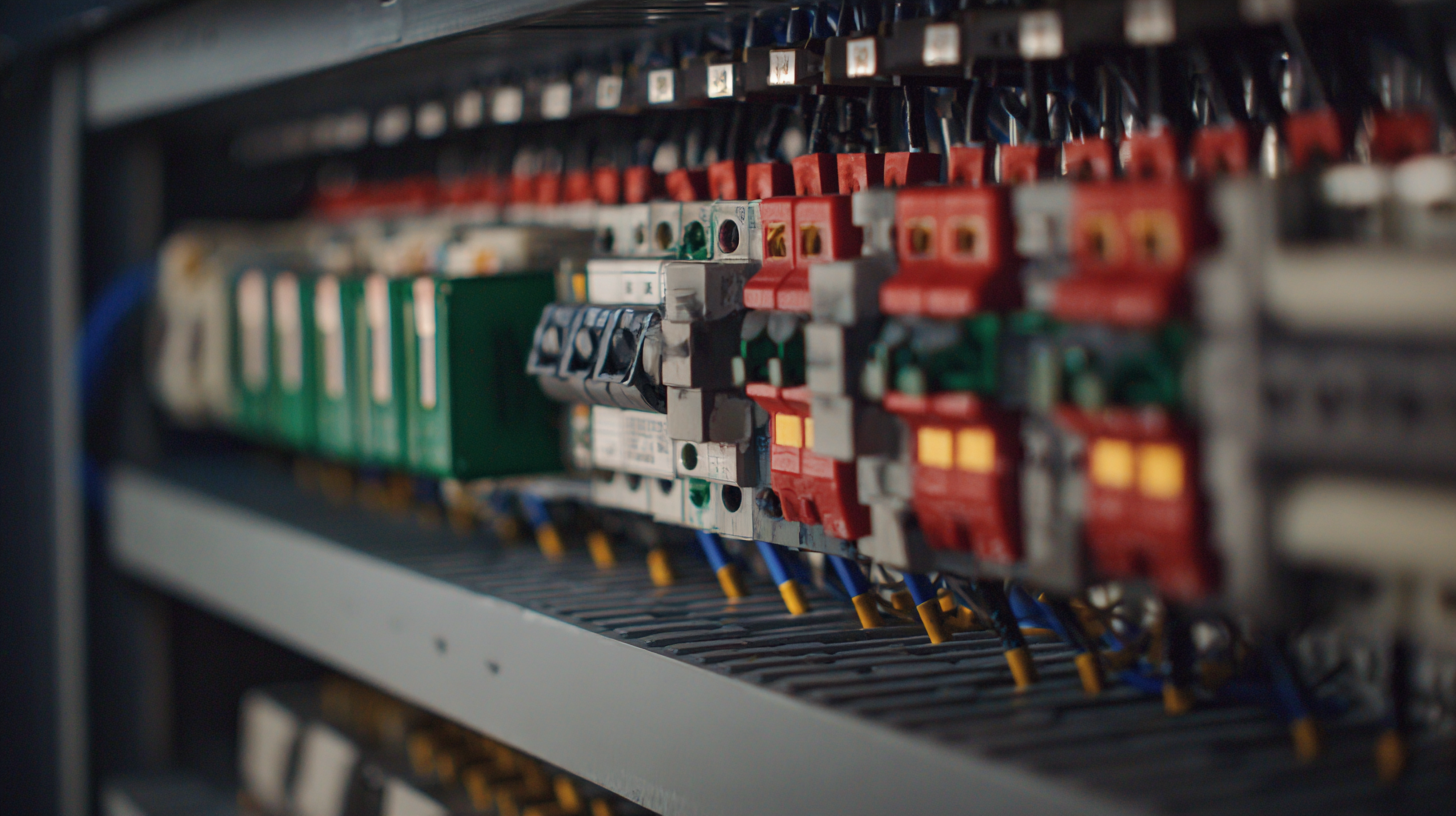

Bus duct systems are critical components in industrial electrical infrastructure, providing a reliable means of distributing electric power from transformers to various loads. The most common types of bus duct systems include insulated bus ducts, uninsulated bus ducts, and busway systems. Insulated bus ducts are particularly valued for their compact design and high current-carrying capacity, making them a preferred choice in facilities with limited space. According to an industry report by the International Energy Agency, systems that employ insulated bus ducts can enhance energy efficiency by up to 30% compared to traditional wiring methods.

In addition, uninsulated bus ducts are often utilized in large factories and plants due to their ability to handle high power loads while minimizing installation costs. They are also ideal for applications where maintenance and accessibility are prioritized, as they usually require less protective covering. Recent trends indicate a shift towards modular busway systems, which offer enhanced flexibility and scalability for evolving industrial needs. A study by the Electric Power Research Institute highlights that the adoption of modular bus duct solutions can lead to a 20% reduction in installation time, ultimately translating to significant cost savings and reduced operational downtime in industrial environments.

Bus ducts, also known as busways, are an essential component in modern electrical systems, providing a streamlined and efficient means of distributing electricity. One of the primary benefits of implementing bus ducts is their ability to enhance energy efficiency. Unlike traditional wiring systems, bus ducts minimize energy losses due to their lower resistance and compact design. This reduction in energy loss translates to significant cost savings for businesses, making them a smart investment for those looking to reduce operational expenses.

Another key advantage is the ease of maintenance and flexibility in design provided by bus ducts. These systems can be easily modified or expanded without the need for extensive renovations, allowing businesses to adapt to changing energy demands. Furthermore, bus ducts improve safety by reducing the risk of overheating and electrical failures, thanks to their enclosed nature and efficient cooling properties. By choosing bus ducts, organizations can not only boost their energy efficiency but also enhance the overall reliability of their electrical systems.

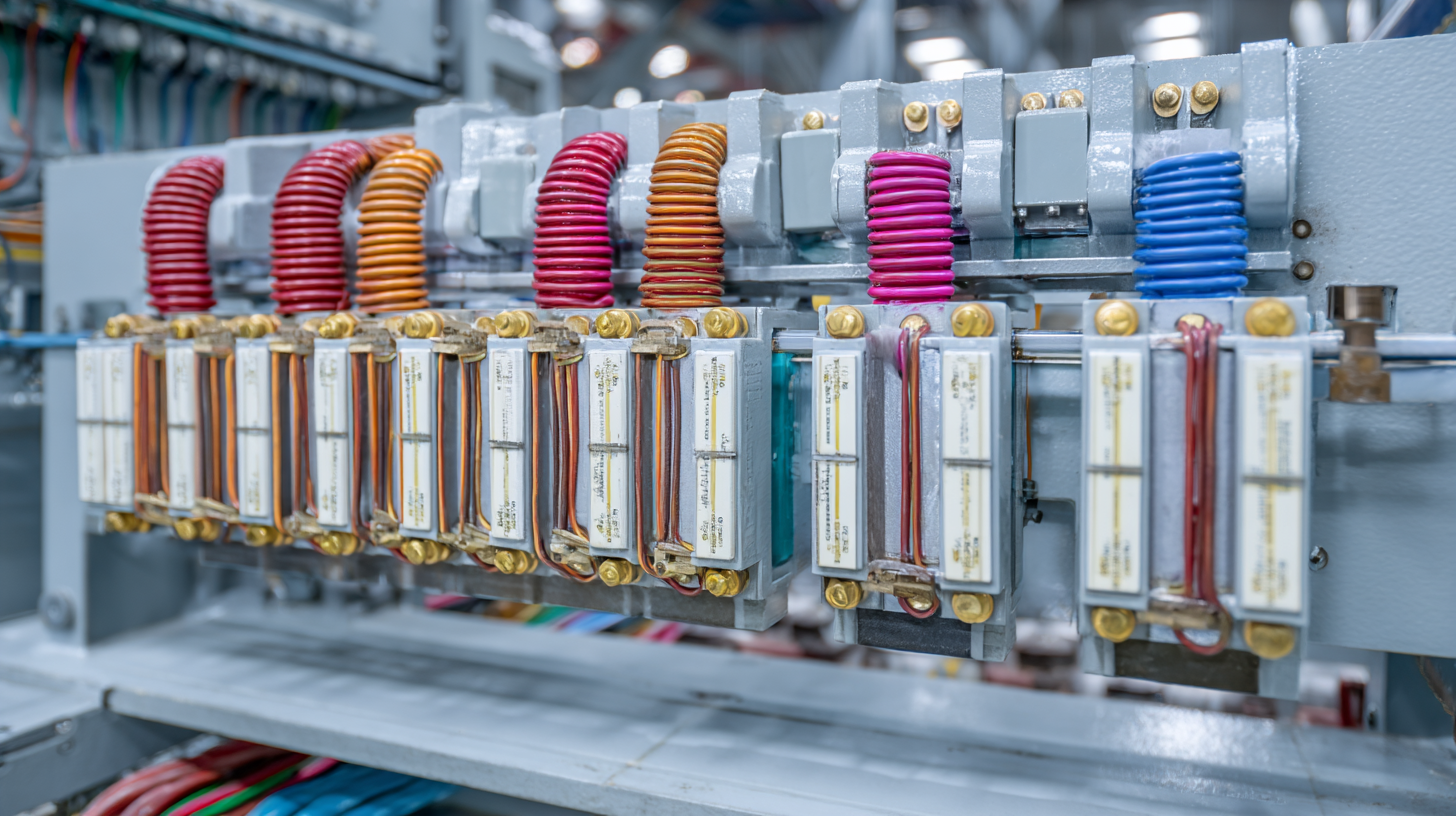

When considering the design of a bus duct electrical system, several crucial factors can significantly impact energy efficiency. Firstly, the choice of material is paramount. Copper and aluminum are the two main materials used for bus ducts, with copper offering lower resistivity and better thermal conductivity. According to a 2022 report from the Electrical Power Research Institute, switching from aluminum to copper can improve overall energy efficiency by up to 20% in high-capacity systems. This not only reduces energy consumption but also minimizes heat generation and potential fire risks.

Another vital aspect is the bus duct's layout and configuration. A well-planned routing minimizes the length of the electrical connections, reducing losses due to resistance. Furthermore, the implementation of insulation and thermal management technologies can enhance performance. For instance, studies indicate that incorporating proper thermal insulation can lower energy losses by 15% or more.

Tip: When selecting a bus duct system, always evaluate the long-term operational costs rather than just the initial investment. Tip: Engage with a qualified electrical engineer early in the design phase to optimize your system for both efficiency and safety. This proactive approach can lead to significant savings and improved system reliability.

Maintenance of bus duct electrical systems is crucial for ensuring optimal performance and energy efficiency. According to a report by the National Electrical Manufacturers Association (NEMA), regular maintenance can enhance system reliability and reduce energy losses by up to 10%. This emphasizes the importance of a proactive maintenance strategy that includes routine inspections and testing of connections and insulation.

Best practices for maintaining bus duct systems include regular cleaning to prevent dust and debris accumulation, which can lead to overheating and decreased efficiency. Additionally, thermal imaging can be employed to identify hot spots that may indicate underlying electrical issues. A 2022 study published by IEEE revealed that facilities employing thermal imaging as part of their maintenance protocols reported a 15% increase in operational efficiency, highlighting the direct correlation between maintenance practices and energy savings.

Implementing a comprehensive maintenance schedule not only prolongs the lifespan of bus duct systems but also contributes to sustainability efforts. The U.S. Department of Energy notes that well-maintained electrical systems can lead to a decrease in carbon emissions, aligning with modern energy efficiency goals. Adopting these maintenance best practices is essential for any facility looking to optimize both performance and energy use.

Future trends in bus duct technology are paving the way for significant improvements in energy efficiency, addressing the growing demand for sustainable solutions in electrical systems. According to a recent industry report by the International Energy Agency (IEA), implementing advanced bus duct systems can enhance energy efficiency by up to 15%, primarily by reducing energy losses associated with inefficient wiring and connections. Innovations such as low-resistance conductive materials and modular designs are being adopted to facilitate optimized power distribution while minimizing installation time and costs.

Tips: When considering upgrades to bus duct systems, evaluate the use of aluminum and copper hybrid configurations, which can significantly reduce weight and improve conductivity. Additionally, integrating smart technologies, such as IoT-enabled sensors, can facilitate real-time monitoring of energy usage, allowing for more informed decisions that maximize efficiency.

As manufacturers focus on enhancing thermal management capabilities, new bus duct designs are incorporating advanced cooling techniques to further decrease energy losses. According to the latest market analysis by Frost & Sullivan, these advancements could lead to a reduction of operational costs by as much as 25% in large-scale facilities. This trend highlights the importance of continuously evolving electrical infrastructure to meet both operational and environmental standards.

Tips: Embrace predictive maintenance by deploying sensors within bus duct systems to detect anomalies early and prevent downtime, ensuring that energy efficiency remains optimal throughout the system's lifecycle.

| Dimension | Current Value | Future Projection (2025) | Impact on Energy Efficiency (%) |

|---|---|---|---|

| Installation Cost ($/m) | 150 | 120 | 15 |

| Voltage Drop (V) | 5 | 3 | 10 |

| Maintenance Frequency (Yearly) | 2 | 1 | 20 |

| Efficiency Rating (%) | 90 | 95 | 5 |

| Lifespan (Years) | 25 | 30 | 8 |