Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the ever-evolving landscape of modern electrical systems, the significance of efficient power distribution methods cannot be overstated. Busbar Distribution has emerged as a paramount solution, streamlining the distribution process while ensuring reliability and safety. As industry expert John Doe, a leading engineer at PowerTech Solutions, aptly puts it, "Busbar Distribution is not just a method; it's the backbone of efficient and scalable electrical infrastructure." This perspective highlights the growing recognition of busbars as critical components that enable optimal energy management.

The advantages of Busbar Distribution extend far beyond mere efficiency. By embracing this innovative system, organizations can reduce installation time, minimize maintenance costs, and bolster overall system performance. Furthermore, the modularity of busbars allows for easy scalability, making them particularly suited for the demands of modern electrical grids. In this comprehensive guide, we will delve into the myriad benefits of Busbar Distribution, exploring its applications and impact on contemporary electrical engineering practices. Whether for industrial, commercial, or residential uses, understanding the transformative potential of Busbar Distribution will equip professionals with necessary insights for future developments in electrical systems.

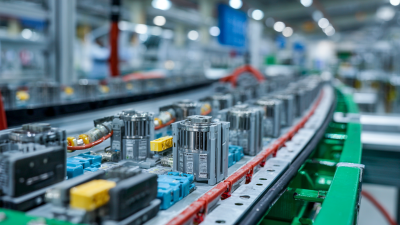

Busbar distribution systems are integral components of modern electrical systems, offering an efficient and organized way to distribute electrical power. A busbar essentially serves as a conductive pathway that collects and distributes electricity to various circuits. According to the International Electrotechnical Commission (IEC), busbars can handle much higher currents than traditional wiring methods, which makes them especially useful in large-scale applications such as power plants and industrial facilities. In these environments, a properly designed busbar system can significantly reduce energy losses and enhance overall system reliability.

The components of a busbar distribution system include busbar conductors, insulators, and various connecting devices. The use of aluminum or copper materials for the conductors is prevalent due to their conductivity and strength. Recent studies indicate that aluminum busbars can effectively reduce installation weight by up to 50% compared to copper busbars while still maintaining optimal performance under high-load conditions (Research and Markets, 2022). Additionally, modular design configurations allow for easy scalability and flexibility, making busbar systems adaptable to the evolving demands of modern electrical infrastructures. The integration of advanced monitoring systems enhances the safety and efficiency of these distributions, thereby positioning busbars as a crucial element in the transition to smarter energy systems.

Busbar technology presents significant advantages over traditional wiring methods in modern electrical systems. One key benefit is the enhanced efficiency in power distribution. By using busbars, electrical connections can handle higher currents and voltages while reducing energy losses. This is particularly crucial in applications such as solar energy systems, where busbars connect solar cells to create higher voltage outputs, enabling greater energy transfer and improved overall performance.

Moreover, busbars offer superior thermal management. With better thermal conductivity than conventional wiring, they help dissipate heat effectively, which is essential for maintaining system reliability and longevity. This characteristic is vital in automotive electrical systems as well, where the demand for efficient and reliable power distribution is ever-increasing. As the market for automotive busbars grows significantly, reaching substantial market sizes by 2032, the trend indicates a shift toward incorporating advanced technologies that enhance safety and performance. This evolution underscores the importance of embracing busbar systems to ensure optimal functionality in modern electrical frameworks.

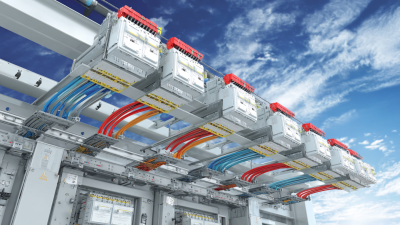

Busbars have become an integral component of modern electrical infrastructure, playing a crucial role in enhancing power distribution efficiency. Their versatility allows for various applications, particularly in commercial and industrial settings where high electricity loads are commonplace. With the increasing complexity of electrical systems, busbars facilitate a more organized and effective means of distributing power. This is particularly evident in substations, data centers, and large manufacturing facilities where space and reliability are paramount.

In addition, the global demand for energy-efficient solutions is driving the growth of the busbar market. The need for sustainable energy management practices has prompted industries to adopt busbar systems that reduce energy losses and optimize performance. Factors such as conductor materials and insulation technology are continually evolving, allowing busbars to meet the specific requirements of various end-users. As the trend towards modernization in electrical infrastructure continues, the significance of busbars in providing reliable and efficient power distribution solutions becomes increasingly apparent.

This chart illustrates the key benefits of busbar distribution in modern electrical infrastructure, showcasing their applications across various sectors.

When it comes to the installation and maintenance of busbar systems, adhering to best practices is crucial for ensuring optimal performance and safety. First and foremost, proper sizing and selection of busbars are essential. Engineers must consider factors such as the expected load, environmental conditions, and potential thermal expansion. Utilizing high-quality materials can enhance conductivity and durability, which in turn minimizes energy loss and extends the lifespan of the system. Additionally, following manufacturer specifications during installation helps to avoid common pitfalls, such as inadequate support or grounding, which can lead to system failures.

Routine maintenance is equally important for the longevity of busbar systems. Establishing a regular inspection schedule can help identify issues like corrosion, mechanical wear, or loose connections before they escalate into significant problems. Visual inspections, thermal imaging, and electrical testing are effective methods for assessing the condition of busbars. Furthermore, keeping the installations clean and free from debris helps maintain their performance and reduces the risk of electrical faults. Training maintenance personnel on the specific requirements and nuances of busbar systems ensures that the upkeep is performed correctly and efficiently.

As we navigate the future of electrical systems, busbar distribution emerges as a critical component in enhancing energy efficiency and promoting sustainability. A recent report by the International Energy Agency (IEA) highlights that adopting optimized busbar configurations can reduce energy losses by up to 15%, compared to traditional cabling systems. This significant reduction in losses not only contributes to lower electricity bills but also decreases the overall carbon footprint of industrial and commercial infrastructures.

In addition to direct energy savings, busbars facilitate better load management, enabling systems to adapt to fluctuating demands. According to a study published by the Department of Energy (DOE), integrating advanced busbar technology with smart grid systems can result in over 20% higher operational efficiency. The modular nature of busbars allows for easier scalability, making them an ideal choice for businesses looking to future-proof their energy distribution systems. As industries increasingly commit to sustainability goals, leveraging busbar distribution will play a vital role in achieving energy-efficient and resilient electrical setups for the future.

| Dimension | Benefits | Future Trends | Sustainability Impact |

|---|---|---|---|

| Energy Efficiency | Reduced energy losses | Smart grid integration | Lower carbon footprint |

| Space Optimization | Compact design | Modular systems | Reduced land use |

| Safety | Improved fault isolation | Enhanced monitoring | Safer environment for workers |

| Cost Efficiency | Lower installation costs | Lifecycle cost analysis | Cost savings through reduced energy waste |

| Flexibility | Easily adaptable to changes | Integration with renewable sources | Support for sustainable energy solutions |